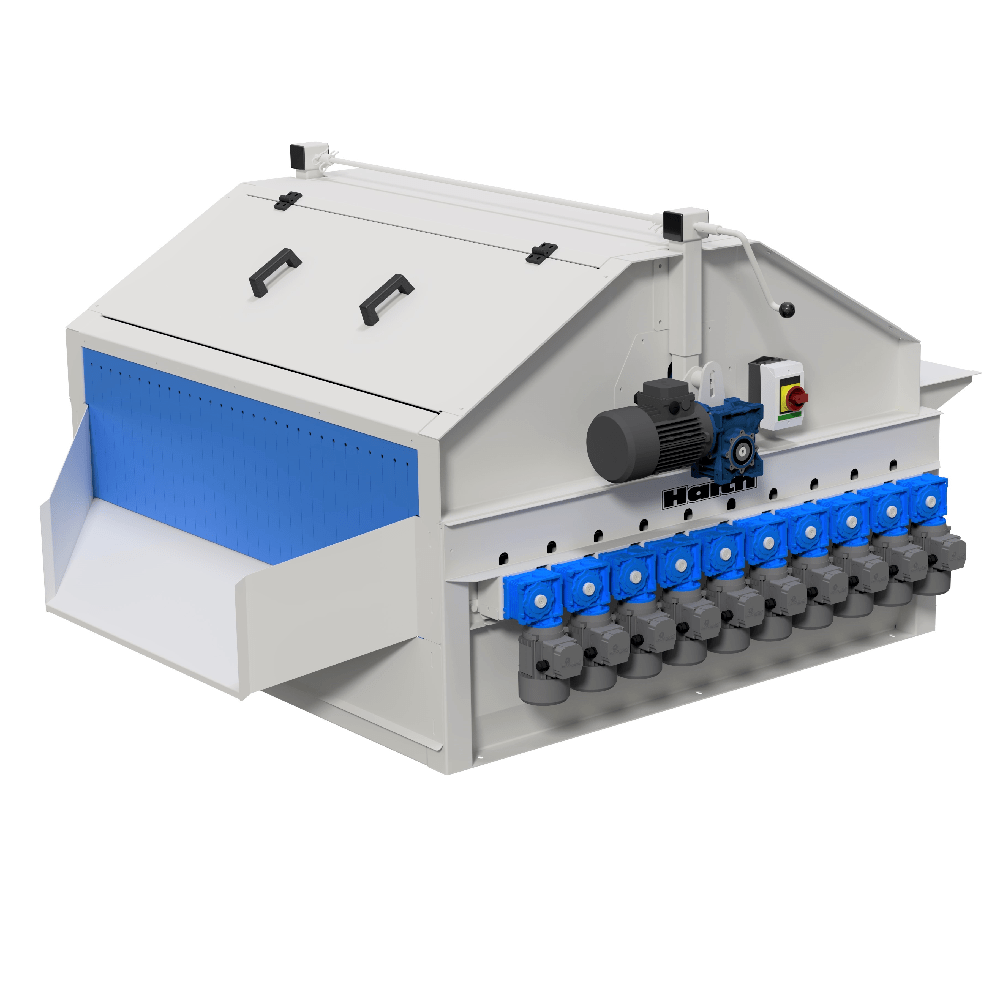

Haiths Direct Drive Dry Brusher cleans crops prior to further processing.

The machine is a popular addition to potato lines prior to packing in to 25kg bags for example or as part of a seed grading system before chemical application.

Onion lines also benefit with the removal of loose skins, surface soil and mould.

A bypass system is usually a requested addition when installing a dry brusher and allows crops with more delicate skins, such as early green top potatoes, to be processed on the same line.

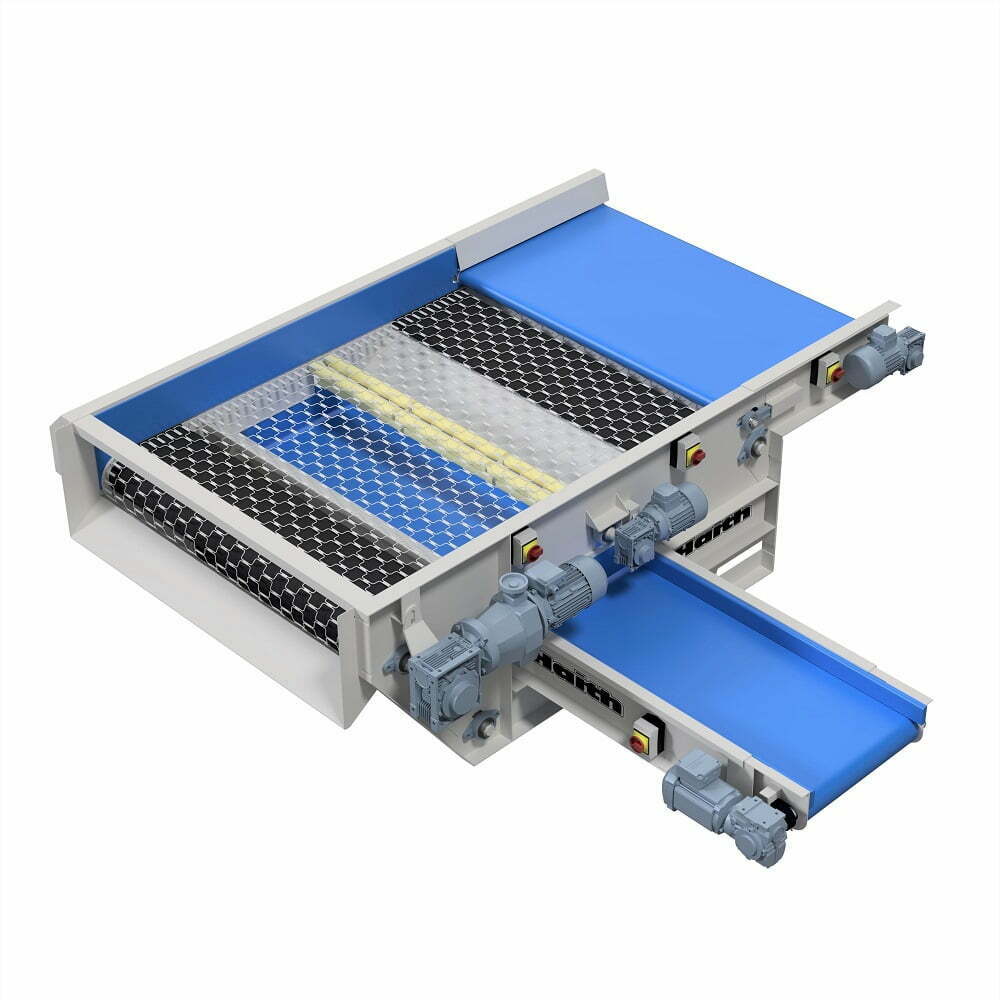

The machines are available with multiple roller configurations and have innovative options including a counter rotating top brush and bed angle adjustment to maximise crop cleaning potential.

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.

Standard features

- Heavy duty shaft mounted drives

- Hinged canopy over brushes

- Variable speed drives

- Dust collection chute under brushes

Optional features

- Adjustable counter rotating top brush

- Sliding bypass system

- Bed angle adjustment

- Electrical clearing system for produce removal from rollers

- Stainless or mild steel construction

Here at Haith we are proud to say that we are one of the only companies in our sector to be continuously owned by the same family since the company was founded.

It all began when, at 18 years old, Geoff Haith started carrying out repairs for local farmers leading him to realise that there was a need for a more mechanised way of washing and grading root vegetables, with his engineering ability and farming background he designed and manufactured machines for carrot, potato and beetroot handling.

The business, until recently, has been run by Geoff’s five sons and daughter, backed by a great young management team to ensure the continued success of the company, there are over 120 people employed at our factory in the UK and multiple agents around the world promoting the Haith brand globally resulting in a network of excellent installations and satisfied customers worldwide.

Haith has continued to grow in size and strength and has moved on 3 occasions to larger premises with more production area, this has led to the present ultra-modern wholly owned facility with around 6,000 m² of production space on a 6 acre site in South Yorkshire which is equipped with the most up to date CNC laser, waterjet and bending equipment.

Haith have achieved many awards for machine design over the years and are especially proud to have twice been awarded the highest accolade in the UK, The Queen’s Award for Enterprise, both times in the Innovation category, as the only company in the field to hold this prestigious award, Haith’s emphasis on continual innovation and development with a view to keeping the UK vegetable industry at the forefront of technology has been acknowledged.

Request more information

on this machine

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.