As labour becomes increasingly scarce, a key challenge facing growers is sourcing workers to manually sort the crop as it goes into store or loaded out onto transport to their customers.

Automating the process of sorting the trash and stone accurately from the good tubers has the potential to significantly increase throughput and save growers many of the costs and issues involved with manual picking.

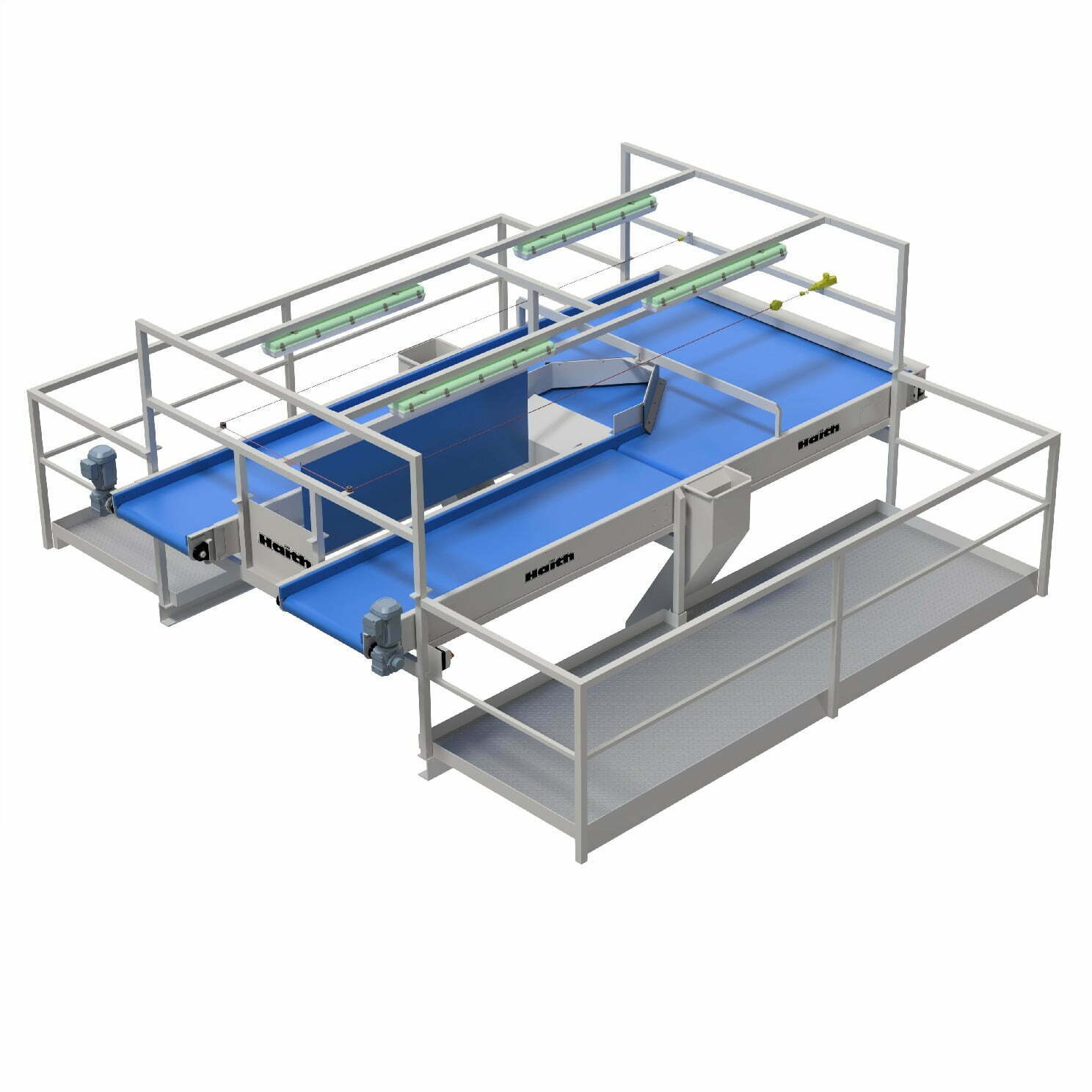

GRIMME and Haith now offer two new optical sorting solutions that do just this, the Haith ProSort being one of them. Optical sorting is not new, and TOMRA is widely acknowledged as a leader in this type of technology.

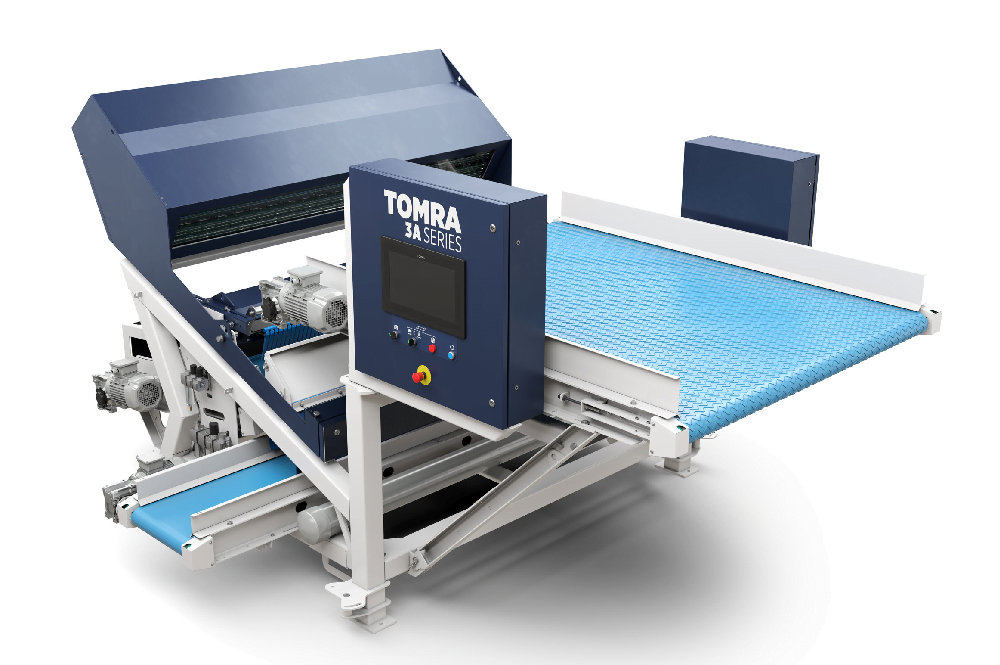

The advanced TOMRA 3A optical sorter is capable of unrivalled foreign material removal, this highly efficient machine is powerful and robust, easy to use and maintain & reduces storage needs.

However, what is new is how the technology has been incorporated by Haith and GRIMME into a new mobile, modular unit that fits quickly and easily into existing processes.

For example:

- Used in conjunction with the GRIMME RH receiving hopper taking potatoes into store

- Used alongside the GRIMME Cleanloader ensuring that the potatoes being loaded are precleaned to the highest standard

- Used as part of a new or existing Haith grading line to sort and clean the incoming crop

- Used exactly when and where the grower or processor needs rapid, accurate cleaning

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.

Standard features

- Fully mobile system packs neatly away with drawbar & road lights

- Coil soil extractor

- Tomra 3A optical sorter

- Manual inspection area

- Touchscreen HMI control

- Full length PVC canopy

- Additional electrical sockets for infeed/outfeed equipment e.g. box filler

- On board compressor

Optional features

- Integral bulk receiving hopper

- GRIMME MultiSep

- Adjustable coil or star separators

- Evolution Separator

- TOMRA 3A: 1200 / 1600 / 2400 widths

- Fixed or mobile system

Here at Haith we are proud to say that we are one of the only companies in our sector to be continuously owned by the same family since the company was founded.

It all began when, at 18 years old, Geoff Haith started carrying out repairs for local farmers leading him to realise that there was a need for a more mechanised way of washing and grading root vegetables, with his engineering ability and farming background he designed and manufactured machines for carrot, potato and beetroot handling.

The business, until recently, has been run by Geoff’s five sons and daughter, backed by a great young management team to ensure the continued success of the company, there are over 120 people employed at our factory in the UK and multiple agents around the world promoting the Haith brand globally resulting in a network of excellent installations and satisfied customers worldwide.

Haith has continued to grow in size and strength and has moved on 3 occasions to larger premises with more production area, this has led to the present ultra-modern wholly owned facility with around 6,000 m² of production space on a 6 acre site in South Yorkshire which is equipped with the most up to date CNC laser, waterjet and bending equipment.

Haith have achieved many awards for machine design over the years and are especially proud to have twice been awarded the highest accolade in the UK, The Queen’s Award for Enterprise, both times in the Innovation category, as the only company in the field to hold this prestigious award, Haith’s emphasis on continual innovation and development with a view to keeping the UK vegetable industry at the forefront of technology has been acknowledged.

Request more information

on this machine

Speak to our specialists

Call us on 01302 831911 and chat to a member of our team for more information about our industrial food handling equipment.